Did you know?

On average, plant & equipment account for 71% of mechanisms related to worker fatalities1. Under WHS legislation, the principal duty of employers is to provide information, instruction, training, and supervision to employees.

Are your plant & equipment critical controls effective?

Can your organisation actually verify effectiveness?

Recently, Safe Work Australia published a new Code of Practice (COP) on Managing the risks of plant in the workplace, released in December 2023.

Code of Practice (CoP) Amendments:

Section 4.6 Roll-ways

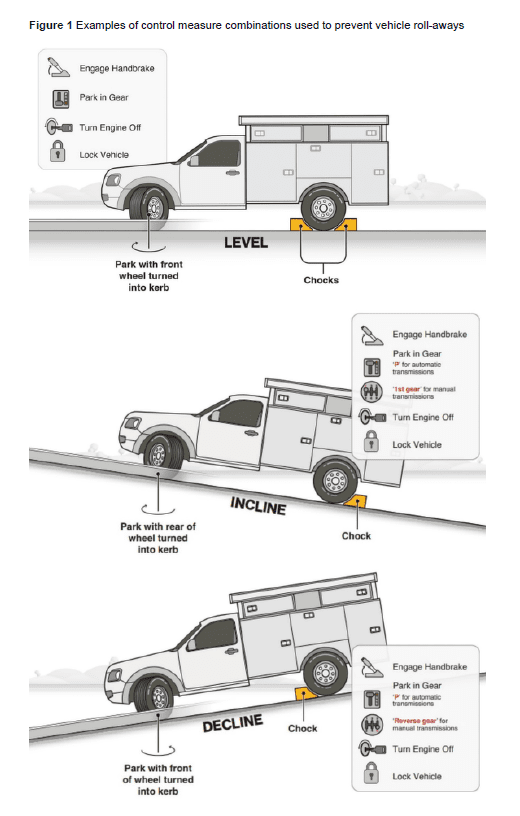

- Vehicle roll-aways refer to the unintentional movement of a vehicle that has not been properly immobilised. This has been a major cause of work-related fatalities and injuries in Australia.

- Sets the guidelines for preventing Vehicle roll aways on flat or sloped terrain.

- The correct placement of wheel chocks which must be at the centre of the wheels.

Click here to access Safe Work Australia’s fact sheet that shows examples of how control measures can be used in combination to help prevent vehicle roll aways.

Other Mobile Plant Critical Controls

Additoinal tips for managing mobile plant critical controls:

- MUE: Be clear on Material Unwanted Events (MAU) and causal pathways

- Critical Controls: Differentiate between “Critical Controls” vs enabling controls, e.g. separating people and plant vs SWMS and training

- Building Capability: Consider setting clear expectations on performance criteria and realted owenrship

- Verifying: Check crticial controls are effective across agreed touch points

- Improve: Review, benchmark, learn and improve, e.g. what are your peers doing in other regions, and industries?

For more information about Critical Risk Control Management, refer to our blog.

1. Source: SafeWork Australia 5-year average 2016-2020.

- Includes: vehicle collision*, Being hit by moving and falling objects, being trapped between stationary and moving objects and trapped by moving machinery and rollover of non-road vehicle

- Excludes: “Contact with electricity, falls from heights, drowning, slide or cave-in, contact with hot objects, being hit by an animal, and other mechanism

*vehicles = cars and trucks, aircraft, boats, loaders, tractors and quad bikes.