Audit & Assurance

Consulting has an expert team of consultants available across Australia and New Zealand to provide independent audit activities.

Contractor Health and Safety

We provide expert advice across the end-to-end lifecycle of contractors and suppliers.

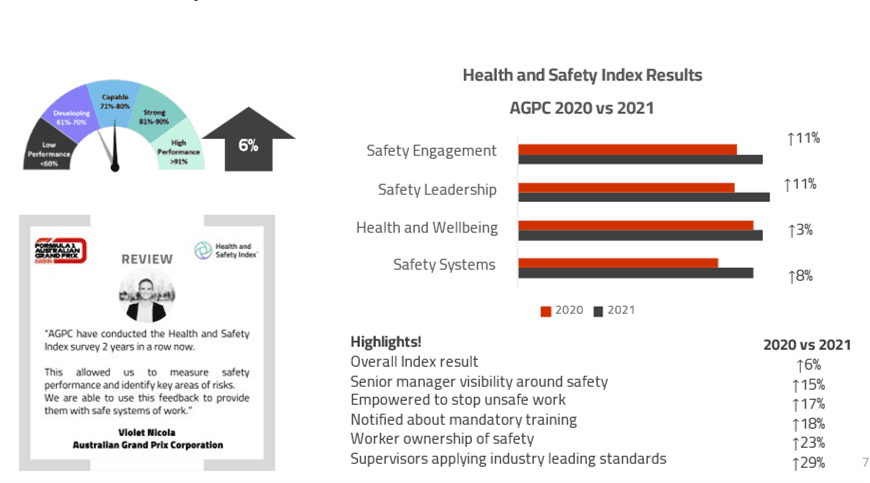

Health and Safety Index

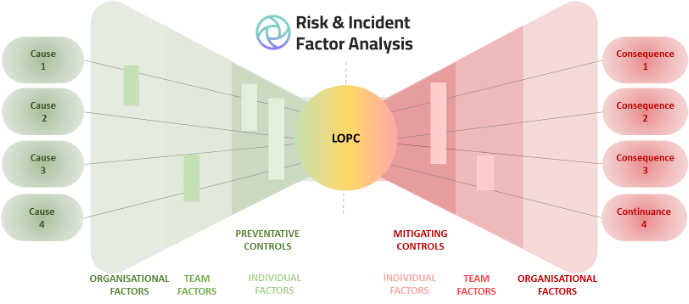

Incident Investigations

Consulting has designed a unique Risk and Incident Factors Analysis (RIFA)

Leadership Development

Consulting specialise in helping organisations assess, focus and improve their approach to building high-performance cultures with targeted safety interventions

Management Systems (ISO & FSC)

Consulting has extensive experience in developing, evaluating and auditing health, safety, environmental and quality management systems

Outsourced Health and Safety Experts

We provide flexible health and safety Business Process Outsourcing (BPO) options at speed.

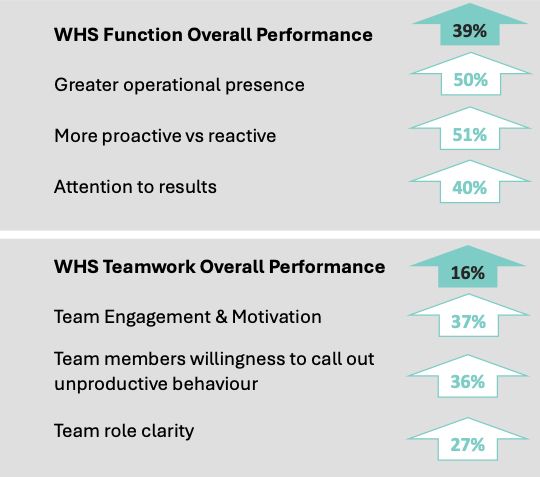

WHS Performance (Maturity) Assessment

Diagnostic (Dx): Statistically reliable survey benchmarks to seek feedback at scale and build high performance

Strategy 4 Safety (S4S)

Strategy 4 Safety (S4S) applies leading industry practices for organisational business strategy to support safety professionals with health and safety strategy.

Training & Competency

Mental Health Training

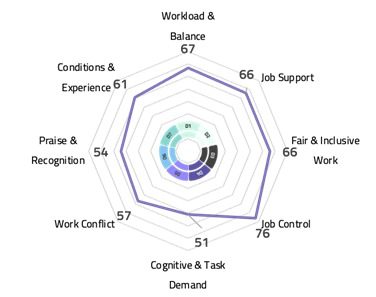

Psychosocial Dx Survey

Consulting has multidisciplinary team to apply global evidence & research informed practices into practical mental health & wellbeing programs for our clients.

Psychosocial Risk Assessments

Consulting has multidisciplinary team to apply global evidence & research informed practices into practical mental health & wellbeing programs for our clients.

Psychosocial Illness Investigations

Consulting has multidisciplinary team to apply global evidence & research informed practices into practical mental health & wellbeing programs for our clients.

Critical Risk Control Management

Critical risk control management enables organisations to target the critical few assist boards

Event Safety

We enable infrastructure and operations plan, build and deliver successful events.

Federal Safety Commissioner

Safety in Design (SiD)

Consulting value the benefits of applying effective safety in design early in the asset lifecycle.

Safety Software & Technology

Translate tech talk into simple solutions to enable high performance.

Transport Safety

Consulting help organisations simplify and manage Chain of Responsibility